Automatic 3D Vertical Effect Mural Art Wall Intelligent Inkjet Printer Printing Machines for Painting Metal Glass

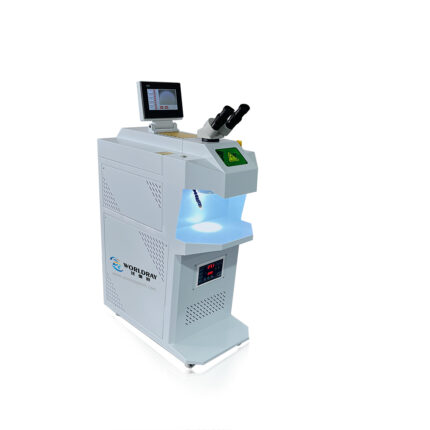

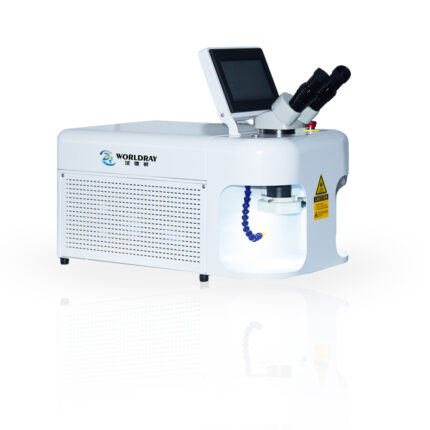

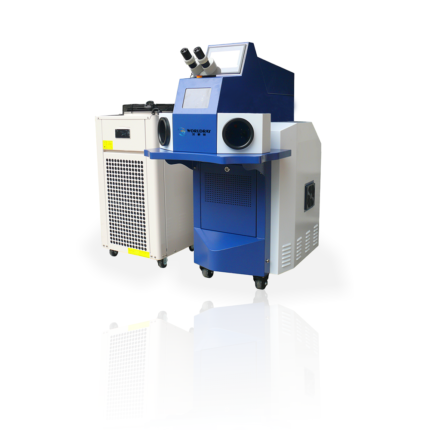

DR-W400 automatic mold welding adopts German YAG solid-state laser technology, which has the characteristics of high peak power, high energy density, and stable performance. It is widely used in the welding and repair of various large, medium, and small mold steels, iron, aluminum, and copper. Advanced digital pulse control inverter technology enable precise adjustment of welding parameters over a large range, achieving low welding repair heat, high-strength welding, and avoiding annealing, discoloration, deformation, and other phenomena.

Model: DR-T3

Intelligent control

High-Speed

High-Precision

PRODUCT DETAILS

DR-W400 automatic mold welding adopts German YAG solid-state laser technology, which has the characteristics of high peak power, high energy density, and stable performance. It is widely used in the welding and repair of various large, medium, and small mold steels, iron, aluminum, and copper. Advanced digital pulse control inverter technology enable precise adjustment of welding parameters over a large range, achieving low welding repair heat, high-strength welding, and avoiding annealing, discoloration, deformation, and other phenomena.

High Precision & Quality

Achieve flawless metallurgical fusion with inert gas protection, eliminating oxidation and discoloration. Precision welding (0.3mm minimum) preserves original surfaces, minimizes excess material, and allows post-weld machining (milling, filing). Ideal for intricate mold repairs without compromising structural integrity.

Ultra-Fast & Efficient Performance

Boost productivity with industry-leading speeds up to 100mm³/min in cold welding applications. Micro-heat technology prevents substrate annealing or distortion, ensuring rapid repairs while maintaining material properties. Perfect for high-volume mold restoration.

Intelligent Power & Adaptability

Microchip-controlled power allocation optimizes energy for diverse materials (0.1–1.0mm wires). Stable output withstands ±20% voltage fluctuations. Quick magnetic connectors enable hassle-free setups for unlimited workpiece sizes, enhancing operational flexibility.

Versatile Welding Modes & Material Compatibility

Supporting multi-mode welding (micro-beam, resistance, precision argon) with adjustable pulses/currents. Compatible with most metals (copper, aluminum) except low-melting alloys. Tunable argon flow ensures stable arcs even at minimal currents for consistent, high-quality results.

Parameter of Equipments

|

Parameter |

Specification |

|---|---|

|

Model |

DR-W400 |

|

Laser power |

400W |

|

Laser wave length |

1064nm |

|

Current regulation |

10--350A |

|

Laser frequency |

1--100HZ |

|

Pulse width |

0.1--20MS |

|

Electric cantilever stroke |

X150mm Y100mm Z150mm |

|

Manual workbench format |

X450mm Y350mm |

|

Control method |

SCM |

|

CCD |

1080P colored belt crosshairs |

|

Microscope |

10X |

|

Welding head |

F=110mm |

|

Cooling-down method |

Water-cooled |

|

Weld selection |

0.1---1.0mm |

|

Interiorinput power |

12KW |

|

Input voltage |

AC380V ±10% / 50/60HZ |

Why choose us

Eco-Friendly & Long-Lasting Results

High quality inks resist UV rays, water, and scratches, with 15-20 years indoor and 3-8 years outdoor color retention. – View More

Precision Meets Versatility

Print on walls, tiles, glass, metal, canvas, and more with 9600 dpi resolution and auto-stitching technology for flawless large-scale designs. – View More

Portable & Cost-Effective

Lightweight (45 kg), foldable design, and $0.3/m² ink cost make it ideal for on-site projects and budget-conscious businesses. – View More

Portable & Cost-Effective

Lightweight (45 kg), foldable design, and $0.3/m² ink cost make it ideal for on-site projects and budget-conscious businesses. – View More