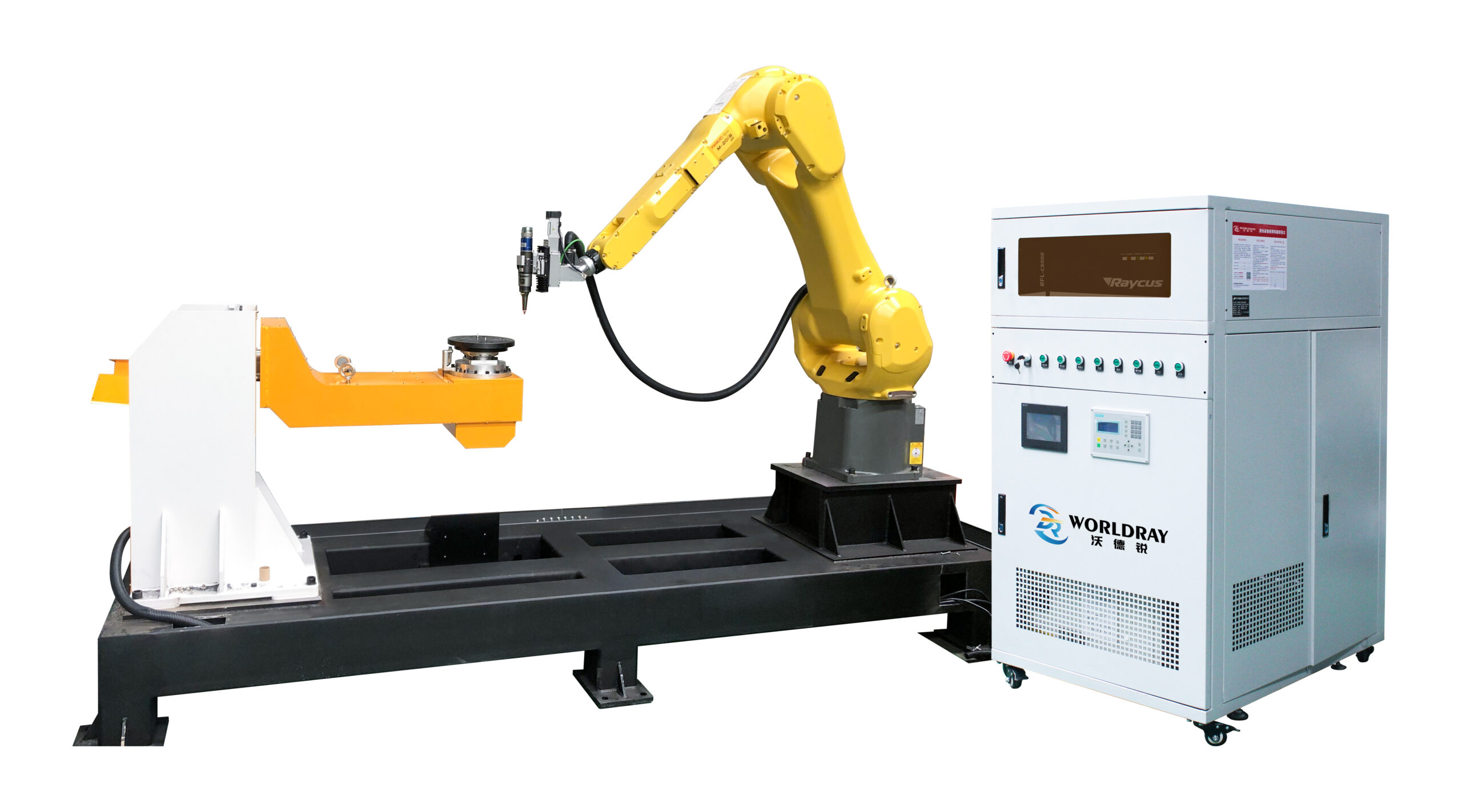

3D Robot Laser Cutting Machine/Workstation: 6-Axis Dynamic 3D High-Precision Cutting Solution for Complex Profiles (0.5–6mm)

Three-dimensional laser cutting machine is the perfect combination of six-axis industrial robot and high-precision laser system, with special design of lightweight three-dimensional anti-collision cutting head, can be a variety of shaped three-dimensional workpiece spatial curve trajectory cutting, and can be added to a number of additional axes to achieve seven-axis, eight-axis linkage. The overall structure is designed in accordance with ergonomics to meet the needs of locomotive manufacturing, helmets and other industry sectors for small and medium batches, diversified flexible processing needs, and to strongly promote the upgrading of industrial intelligence.

Intelligent control

High-Speed

High-Precision

PRODUCT DETAILS

6-Axis Industrial Robot + Fiber Laser Integration

Enables complex spatial curve cutting with optional 7-axis/8-axis expansion for multi-angle processing.

Dynamic 2D/3D One-Pass Cutting

Processes 0.5–6mm thick materials (e.g., aluminum frames, automotive parts, fitness equipment tubes) with smooth, burr-free edges.

Self-Developed PLC Control System

Supports teach programming and offline programming for flexible batch production without molds or post-processing.

3x Faster Than CNC Machining

Reduces labor and assembly time, ideal for R&D and small-to-medium batch production.

Zero Mold Dependency

Eliminates mold costs, shortens development cycles, and allows rapid design changes.

High Precision & Consistency

Achieves ±0.1mm accuracy, meeting strict standards for industries like automotive and aerospace.

Dual-Station Processing

Enhances efficiency by 30% with parallel workpiece loading/unloading.

Eco-Friendly Operation

No consumables, zero pollution, and 95%+ material utilization rate.

Ergonomic Design

Simplified operation for complex 3D surfaces (e.g., helmets, vehicle frames) with lightweight anti-collision cutting heads.

Low Ownership Cost

Compact footprint, minimal maintenance, and energy-efficient performance reduce total lifecycle expenses.

Parameter of Equipments

|

Parameter |

Specification |

|---|---|

|

Laser-type |

Fiber Laser |

|

Laser Power |

Customizable (depends on material) |

|

Repeat Positioning Accuracy |

±0.03 mm |

|

Cutting Wall Thickness |

0.5–15 mm (adjustable based on material) |

|

Cutting Speed |

≤12 m/min |

|

Minimum Cutting Aperture |

≥3 mm |

|

Robot Model |

FANUC-M20iA/B/D, YASKAWA-GP25 |

|

Robot Effective Radius |

1853 mm |

|

Idle Movement Speed |

≤30 m/min (non-cutting state) |

|

Working Area |

2200×1800×200 mm (cutting range depends on workpiece shape and height) |

|

Worktable Load Capacity |

≤25 kg (at flange center) |

|

Input Power |

Three-phase five-wire system AC380V 50Hz |

|

Power Protection Rating |

IP54 |