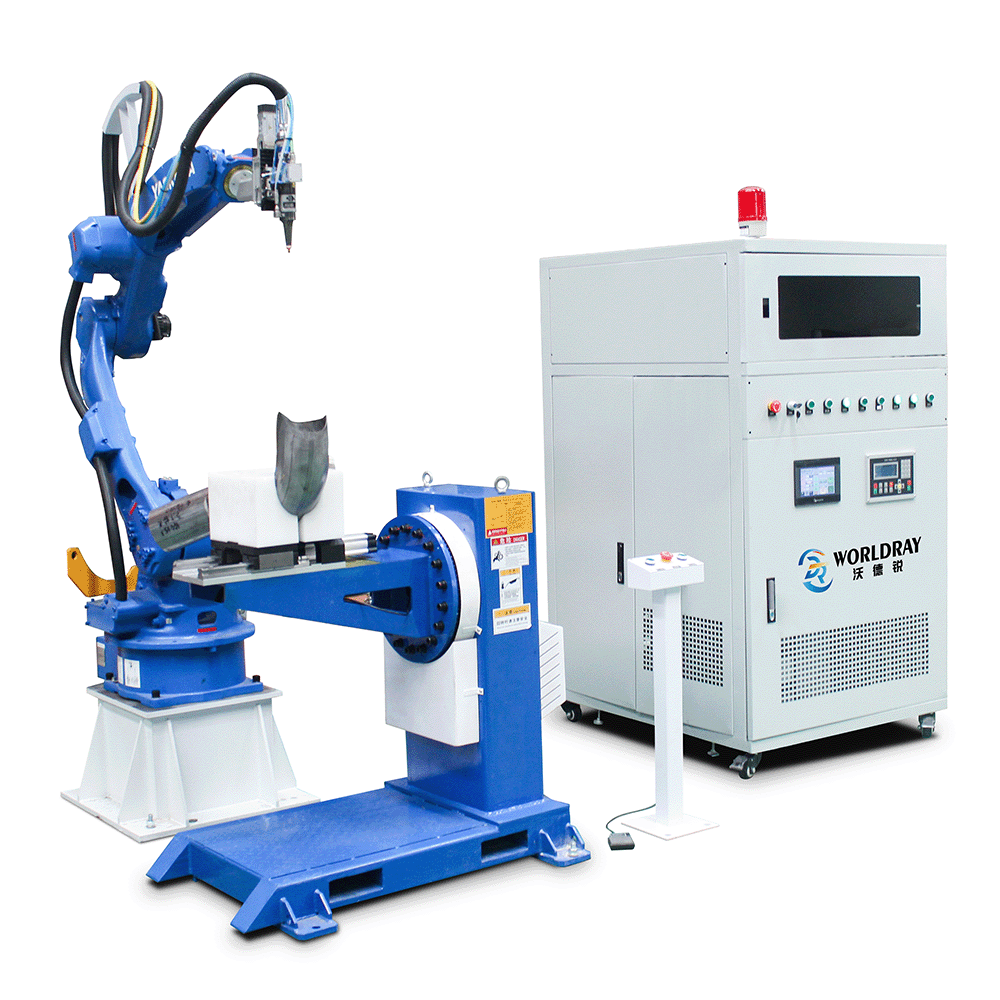

6-Axis Robot Laser Welding Workstation Intelligent Fiber Laser Welding Solution for Complex Metal Parts

The 3D robotic laser welding machine is a highly integrated solution that combines a six-axis industrial robot with a high-power fiber laser system. Designed for automatic and precise welding of large, irregular, or three-dimensional metal workpieces, it supports flexible multi-angle welding without being limited to flat surfaces. With features like high speed, high precision, and stable quality, it is ideal for mass production and high-performance industrial applications.

Eco-Friendly

High-Level Automation

Cost-Efficient & Productivity Boosting

PRODUCT DETAILS

Six-Axis Robotic Welding

Powered by ABB or Yaskawa six-axis robots, allowing multi-directional, complex spatial welding with high repeatability.

Multi-Station Smart Workflow

While one station is welding, others can load/unload — minimizing downtime and boosting productivity.

Full/Auto & Semi-Auto Modes

Adaptable for different production scales with easy switching between automatic and semi-automatic operation.

High-Precision Fiber Laser

Equipped with top-tier domestic fiber lasers with adjustable continuous/pulsed output, ensuring beam stability and high-quality welds.

Customizable Laser Spot Shapes

Supports various spot patterns (dot, line, ring, double ring, triangle, figure-8) to suit different seam types and material needs.

Advanced Power Control

Built-in PWM-controlled laser power module with soft ramp-up/ramp-down for consistent, precise weld quality.

Weld Seam Tracking System (Optional)

Real-time detection and tracking of weld seams improves accuracy and reduces operator programming time.

CCD Visual Positioning System (Optional)

Automatic correction of workpiece deviations ensures accurate weld placement, saving time and reducing cycle errors.

Flexible Rail & Motion Expansion (Optional)

Add-on options for robot walking axes, floor/ceiling rails allow expanded work range and reduced unit cost per station.

Easy Programming & Fast Learning

Supports offline and teach pendant programming — basic operation learnable in one day, full proficiency in a week.

Parameter of Equipments

|

Parameter |

Specification |

|---|---|

|

Robot Brand |

ABB / Yaskawa (Optional 6-axis industrial robot) |

|

Welding Type |

Fiber Laser Welding |

|

Laser Power |

1000W / 1500W / 2000W / 3000W / 6000W(optional) |

|

Laser Source |

Continuous Fiber Laser |

|

Laser Wavelength |

1070 ±10 nm |

|

Welding Head |

Single/Dual-axis Swing Type with Safety Protection |

|

Spot Shape Options |

Dot, Line, Circle, Double Circle, Triangle, Figure-8 |

|

Welding Thickness Range |

0.5 – 4.0 mm |

|

Welding Width |

0.4 – 3.0 mm (adjustable) |

|

Positioning Accuracy |

±0.03 mm |

|

Repeatability |

±0.02 mm |

|

Cooling Method |

Water Cooling |

|

Control System |

PC-Based or Teach Pendant |

|

Programming Mode |

Online/Offline / Teach Mode |

|

Optional Systems |

Seam Tracking, CCD Vision, Robot Rail Extension |

|

Gas Supply |

Argon / Nitrogen (as required) |

|

Power Supply |

AC 380V / 50Hz (Customizable) |

|

Dimensions (Robot Cell) |

Custom per layout (e.g., 2200 × 1800 × 2000 mm) |

|

Operation Mode |

Full-Automatic / Semi-Automatic |

|

Working Environment |

5°C – 40°C; Humidity ≤ 70% RH |